Blog

Understanding Molecular Sieves 3A: Applications and Benefits for Everyday Use

Molecular sieves are the main materials required for a lot of industries and applications because of their properties of absorption of moisture and separation of molecules. Of these varieties, Molecular Sieves 3A is highly regarded due to the accurate and efficient separation it provides. They are a powerful instrument to guarantee the specifications for certain products, improvement of the industrial operations, and the preservation of perishable goods. In this article, the properties of Molecular Sieves 3A, uses and advantages will be discussed.

Molecular Sieves 3A

Molecular Sieves 3A an example of synthetic zeolite with pore openings of 3 angstroms size. As a result, the pore size of this particular sieve is capable of adsorbing molecules of a relatively small size, such as water molecules, while rejecting the larger ones. This selective adsorption makes them so useful as desiccants in industries where the removal of moisture or molecular sieving is called for. Produced by the leading desiccant producers, 3A Molecular Sieves are employed in petrochemical, pharmaceutical and packaging and sectors. For this reason, their performance is consistent regardless of the surrounding conditions, for example, high temperatures and pressures, therefore they are suitable for most uses. Also, due to their reusability and chemical stability, these particles are preferred in industries that require high efficiency and perfect cost-effectiveness.

Molecular Sieves 3A are not only reliable but also environmentally friendly. Manufacturers assist various businesses to minimize the possible dangers associated with dampness while cutting on expenses due to their conveyability. Also, because of their excellent adsorption rate and operational characteristics under extreme conditions the adsorbent material is an essential component of many industries that need stable and effective moisture removal tools.

Key Applications of Molecular Sieves 3A

Molecular Sieves 3A are very diverse and have a special place as an important material in many industries. In the context of petrochemical processes, desorption of gases and liquids is applied to eliminate the impact of moisture on subsequent reactions and equipment. For instance, they are used in natural gas processing and ethanol production since water has to be removed to high levels of purity.

In packaging, Molecular Sieves 3A acts as a barrier to moisture thus being very useful to industries dealing with moisture sensitive commodities such as pharmaceuticals, electronics and foods by reducing their shelf life by absorbing excess moisture. In insulating glass windows, these sieves are equally found useful to minimize fogging and condensation, reinforce durability and clarity. In addition to industrial application, it is also used in cosmetics and toiletry products due to their ability to balance the rate of moisture in production.

The way the company has applied it in medical devices like oxygen concentrators goes along way in proving its reliability. Molecular Sieves 3A provide enhanced levels of gas purity and are relevant to important medical uses. Due to such flexibility of operation, they are essential for uses that demand accuracy and consistency.

Advantages of Molecular Sieves 3A

The uses of Molecular Sieves 3A are not limited to moisture removal and adsorption processes and other functions as we have seen above. Such features enable them to fix on molecules of specific sizes, stimulating its use in systems, which need high degrees of purity and quality. While compared to other desiccants like silica gel, or activated alumina, Molecular Sieves 3A is capable of performing at these high temperatures thus making them suitable for application at these conditions.

Other benefits are the ability to be used more than once, and these are quite easier to reuse than glass containers and petri dishes. Those sieves can be used repeatedly without diminishing their performance, which makes them economical and more habitual to the environment as compared to other sieves. Other reliable desiccant manufacturers also make sure that these sieves are manufactured in line with quality standards to offer reliable desiccants all the time. Because they are non toxic and green they are ideal for industries that are working towards environmental conservation.

Further, Molecular Sieves 3A minimize risk in industries because they eliminate moisture to minimize cases of contamination or deterioration. Because of their versatility and impressive ability to work well even in severe environments petroleum based polyols are ideal for use in products as varied as petrochemicals and common consumer goods.

Molecular Sieves 3A Compared with Other Desiccants

The performance of Molecular Sieves 3A is best understood when compared with other desiccants like silica gel or activated alumina. Silica gel is known for general use but in many industrial processes it has to be very selective and only pick up molecules it needs without picking up water molecules. Activated alumina, although can be used in drying, lacks the same degree of selectivity or recyclability as Molecular Sieves 3A.

Molecular Sieves 3A one of the most preferred products attributed to its applications where a rigid molecular separation or moisture elimination in elevated temperature condition is required. Such work outlets endure; they are more dependable and flexible besides being able to work efficiently in extreme conditions as compared to their counterparts. Their responsiveness to precise molecules makes them ideal for application in industries that demand high levels of performance especially as moisture control agents, gas dehydrants, and preservatives for products.

Apart from the performance advantage, the long sieving lifetime of Molecular Sieves 3A is another way through which its use brings cost-effectiveness. To companies aspiring to maximize their operational costs, these sieves minimize waste, guarantee quality, and uniformity of results within many procedures.

Why One Should Choose Molecular Sieves 3A

Molecular Sieves 3A have gained popularity in industries that demand accurate control of moisture and low molecular compounds. They are exceedingly durable, often efficient and can be used in applications where conditions might be harsh, from petrochemical processes to packaging. Manufacturers of desiccant, in particular, advance themselves and enhance everything in connection with the creation of Molecular Sieves 3A to fit the industry standards.

They are also reusable and friendly to the environment, making them an economical solution for companies that want quality without high losses through disposables. From the freshness of packed products, and the transparency of insulating glass vision, to the cleanliness of gases and liquids, Molecular Sieves 3A is an integral necessity of the contemporary social economy.

Summing up, it is possible to conclude that the application of Molecular Sieves 3A is one of the most effective and universal nowadays sort of desiccants. By virtue of this, their versatility, versatility in use, and numerous utility implications make them strategic commodities for industries and daily use. In its essence, these sieves meet all specifications and requirements for industrial procedures or food product preservation. Molecular Sieves 3A is all the more beneficial because these dehydrating agents are known to deliver accurate moisture content control and high reliability for multiple industries across the international markets.

For More Information Visit Loopermagazine

-

Celebrity1 year ago

Celebrity1 year agoWho Is Jordan Broad?: The Untold Story of Ashley Broad Husband

-

Celebrity1 year ago

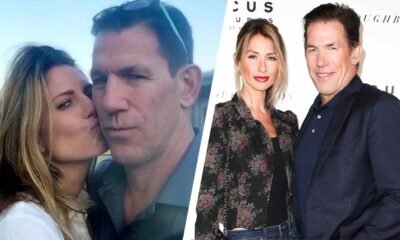

Celebrity1 year agoWho Is Mary Ryan Ravenel?: Inside The Life Of Thomas Ravenel’s Ex-Wife

-

Celebrity1 year ago

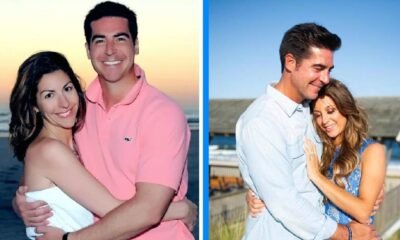

Celebrity1 year agoWho Is Noelle Inguagiato?: The Untold Story Of Jesse Watters Ex-Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Dolphia Parker?: Everything About Dan Blocker’s Wife